NFSA Tech-Notes: Pressure Regulating Devices

This issue of TechNotes was written by Terin Hopkins, NFSA’s Manager of Public Fire Protection.

Pressure is a continuous physical force exerted on or against an object and is a constant balancing act when designing water-based fire protection systems in buildings. While it is basic science, with each cubic foot of water weighing 62.4 lb and exerting a force of .4333 psi for every foot of elevation. It becomes a greater challenge to deal with the higher we build.

Pressure is a continuous physical force exerted on or against an object and is a constant balancing act when designing water-based fire protection systems in buildings. While it is basic science, with each cubic foot of water weighing 62.4 lb and exerting a force of .4333 psi for every foot of elevation. It becomes a greater challenge to deal with the higher we build.

A building is designated as a high-rise once the building is 75 feet/below the lowest level of fire department access, to the highest occupiable floor. This becomes the real starting point in the discussion of pressure requirements and only gets more complex as we reach for the stars.

The International Building Code (IBC) now acknowledges a second building height category for high-rise requirements for buildings above 420 feet. The measurement point for this designation is a bit different and uses building height, which is between the grade plane and the average roof height of the highest roof.

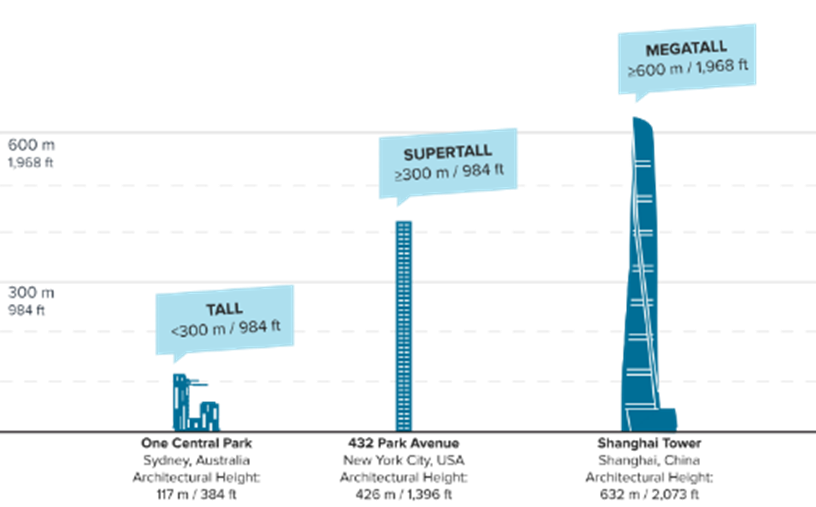

The international community also uses the criteria set by the Council on Tall Buildings and Urban Habitat for designations above those identified in the IBC listing: tall <984 ft, supertall >984 ft, and megatall >1968 ft.

Courtesy of CTBUH

While most buildings are somewhere between a mid-rise and a high-rise with an occasional building extending into the 300 to 500-foot range. Science is the same and the challenges of managing pressure within the required pressure limitations of the codes and standards remain, .4333 psi/.0299 bar every foot.

Pressure Maximums

These buildings require greater pressure the higher they go to achieve the flows needed for the water-based fire protection system installed within them. The requirements for regulating pressure come from the standards, and we commonly use 175 psi as a maximum system pressure provided by both NFPA 13 Standard for the Installation of Sprinklers and NFPA 14 Standard for the Installation of Standpipe and Hose Systems.

These buildings require greater pressure the higher they go to achieve the flows needed for the water-based fire protection system installed within them. The requirements for regulating pressure come from the standards, and we commonly use 175 psi as a maximum system pressure provided by both NFPA 13 Standard for the Installation of Sprinklers and NFPA 14 Standard for the Installation of Standpipe and Hose Systems.

NFPA 20 Standard for the Installation of Stationary Pumps for Fire Protection defines a very tall building as a high-rise building where the fire protection water demand exceeds the pumping capacity of the fire department. NFPA 14 uses this definition to trigger the additional requirements for redundancy in buildings, doubling the complexity of regulating pressure.

NFPA 14 sets a maximum system pressure of 400 psi but has an exception for express risers in accordance with material listings. This makes the manufacturers listing the true only limitation for overall pressure maximums.

Managing Pressure

When we look at the usual ways of managing pressure within a building, it tends to fall into a few categories: zones, water supply, pressure-regulating valves, pump sizes/types and an overall combination approach.

- Zones: Zones allow specific areas of the building to be divided into smaller areas, limiting pressure in those areas of the building.

- Water Supply: Separate water supply sources including dedicated water tanks, gravity tanks, multiple municipal feeds all allow specific design areas to utilize distinctive design pressures.

- Pressure Regulating Valves: The use of direct and indirect acting PRV’s allow the regulation of pressure at specific points within the system or systemwide with a master piloted valve.

- Pumps: Fire pumps increase the system pressure and the use of pumps with specifically designated curves, variable speed pumps or multiple pumps allowing for maximum options for pressure regulating.

- Combination: The combined use of multiple design tools used to manage pressure in buildings will allow for more effective system design.

Redundancy and Acceptance Testing

Buildings designated as above the level of fire department pump capabilities and/or reaching certain height thresholds will require redundancy making system design and the management of pressure more complicated. While many redundant systems are truly independent, in many designs they can build on one another, as is the case with zone used to feeding additional zones as a redundancy measure.

Fire protection system acceptance testing is a crucial step to ensure that the installed fire protection systems meet the required standards and specifications. This is a critical process which often lacks prescriptive requirements for buildings with complex pressure regulating systems, like multiple zoned buildings or when redundant systems are required.

Want to Learn More about Pressure Regulating Devices? Join NFSA’s Tech Tuesday, May 21st, 2024.

There are advantages, disadvantages, and limitations for all of the different tools used for managing the pressure within a building, and we will discuss these issues associated with the utilization of these methods during the upcoming May 21st Tech Tuesday: Pressure Regulating Devices. NFSA members can earn up to 12 CEU hours for free by registering for the association’s Tech Tuesday classes. These classes cover a variety of topics in fire protection, from lithium-ion, antifreeze, and much more. To learn more about membership with our association, visit our membership page.

Further Reading on pressure, pressure regulating devices, and pressure regulating valves:

ROLLS RIGHT OFF THE TONGUE – REGULATING, RESTRICTING AND REDUCING