Nobody Likes Change! Addressing High-Piled Storage Changes to NFPA 13

By Terin Hopkins, Manager of Public Fire Protection

High-piled storage facilities play a vital role in the storage of goods, but also present significant fire hazards if not managed properly. One key aspect of maintaining safety in these facilities is monitoring changes made to commodities and the way they are stored. It’s important for building owners to make proper adjustments not only to the commodities stored but to shelving and fire protection, as changes are made. This practice is essential for reducing fire risks and complying with the regulations of the fire code.

What is High-Piled Storage?

The International Building Code (IBC) 2021 defines high-piled combustible storage as the storage of combustible material in closely packaged piles or combustible material on pallets, in racks or on shelves, where the top of the storage is greater than 12 feet in height. This definition also allows the Authority Having Jurisdiction (AHJ) to designate certain high-hazard commodities like rubber tires, Group A plastics, Flammable liquids, idle pallets, and other similar commodities, where the high exceeds 6-feet in height to be designated as high-piled combustible storage.

General Information Signs for High-Piled Storage

General Information Signs for High-Piled Storage

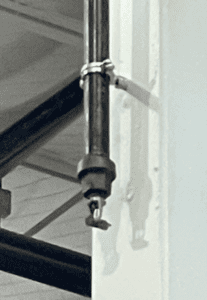

NFPA 13 Standard for the Installation of Sprinklers (2019) Section 28.6* requires a permanent general information sign in addition to the sprinkler Hydraulic Data Plate. The General Information Sign is used to determine system design basis and information relevant to the requirements for inspection, testing and maintenance. This is not intended to be a hazard evaluation of stored commodities but does allow inspectors to know what the system was originally designed to protect.

NFPA 25 Standard for the Inspection Testing and Maintenance of Water-Based Fire Protection Systems, provides guidelines for ensuring the safety of high-piled storage facilities. One critical requirement is making sure a General Information Sign is provided, securely attached and legible. This provides verification that the current system design is appropriate for the commodities being stored and allows for enforcement when inappropriate changes are made to the commodities stored in these facilities.

This practice is essential for several reasons:

- Fire Load Management: Different commodities have varying fire loads, meaning they contribute differently to the intensity and spread of fires. By regularly addressing changing commodities, facilities can manage their overall fire load, and maximize their fire protection systems by making required adjustments and overall reducing the risk of catastrophic fires.

- Compatibility: Some commodities, when stored together, can create hazardous conditions. Changing commodities may inadvertently place incompatible materials together creating potential chemical reactions or catastrophic fires.

- Fire Protection Systems: Over time, commodities can degrade, get damaged, or simply migrate into areas lacking proper fire protection. Modification of fire protection systems is occasionally needed to reduce the potential of fire-related incidents or to address changes made in what is being stored and how it’s stored.

- Compliance: NFPA 25 requires the regular inspection and maintenance of fire protection systems in high-piled storage facilities. Changing commodities is part of this compliance process, ensuring that the owners of these facilities adhere to safety standards and make appropriate adjustments as storage is altered.

These signs provide crucial information about the storage area, including the location of fire protection equipment, maximum storage height, and commodity classifications.

The Owner or Designated Representative’s Role in Fire Protection for High-Piled Storage Facilities

The proper management of changing commodities in high-piled storage facilities is the owner or designated representative’s responsibility and essential for managing fire risks, ensuring compatibility, reducing ignition sources, and complying with fire code safety standards. By adhering to these basic guidelines and regularly addressing any changes with commodities, building owners and owner representatives can enhance the life safety in their building and minimize the risk of fire-related incidents.

More about the Author

Terin Hopkins has 34 years of experience in public safety and is currently the Manager of Public Fire Protection for the National Fire Sprinkler Association. He represents NFSA on many NFPA and UL technical committees, including NFPA 1 Fire Code.

Terin Hopkins has 34 years of experience in public safety and is currently the Manager of Public Fire Protection for the National Fire Sprinkler Association. He represents NFSA on many NFPA and UL technical committees, including NFPA 1 Fire Code.

Have a Question About High-Piled Storage Requirements for Fire Protection? Contact the NFSA Today!

Members and employees of NFSA work very closely in the codes and standards development process. Our team of experts stays on the cutting edge of fire protection issues by participating in over 250 codes and standards development committees.

NFSA members benefit from the association’s involvement in the code development process through a service called Expert of the Day. This service provides members with an answer to even the most difficult codes and standards question.

Additionally, the NFSA’s Expert of the Day Handbooks are a great resource for fire sprinkler contractors, layout technicians, engineers, authorities having jurisdiction, inspectors, and students, and serve as a compilation of the best Expert of the Day Questions going back decades.

If you have an interest in NFSA’s mission to protect lives and property through the widespread acceptance of the fire sprinkler concept, or you simply want to get more involved in the codes and standards process with NFSA, please visit NFSA’s membership page.

General Information Signs for High-Piled Storage

General Information Signs for High-Piled Storage