Where it all begins-Chapter 5 of NFPA 25

Chapter 5 of NFPA 25, Standard for The Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, is where all the tasks and frequency requirements for sprinkler systems can be found. This is one of the most used chapters in the standard as it covers inspection, testing, and maintenance (ITM) of components for all water-based fire protection systems and is appropriately named “Sprinkler Systems.” In this chapter we will find the requirements for sprinklers, sprinkler pipe, hangers, and many other components. It also tells us where we can find information about components found in other chapters.

There are many tasks in Chapter 5 that are important to the operation of sprinkler systems, starting with Section 5.2, inspections. All tasks are laid out in the standard in order of Inspection, testing, and then maintenance. Section 5.2 provides the inspection requirements for sprinklers, sprinkler pipe, fittings, hangers as well as many other components. One of the most overlooked inspections are signs. There are multiple sign requirements in NFPA 25 including control valve, antifreeze, information, and the relatively newly required general information sign. This sign was introduced in the NFPA 25, 2014 edition and has been required at the time of installation since the 2007 edition in NFPA 13.

As you can see, there is a great deal of information contained on this sign that can go a long way in future renovations, as well as for ITM comparison requirements. Remember it was not required by NFPA 13 until 2007, many installing contractors and Authority Having Jurisdictions (AHJ) may not be aware of the requirement. Section 5.2 is the inspection section, simply do things look like they should? Do they appear to be in the proper operating state, not leaking, not damaged? That is the extent of inspections. Now for the fun stuff, Section 5.3 Testing. This is where the real work begins and where things can go wrong if not conducted in the proper manner. This section includes the testing of alarm devices, antifreeze systems and sprinkler testing. One thing you will no longer see in chapter 5 is the testing and calibration of gauges, this was moved to Chapter 13 in NFPA 25, 2017 edition.

As you can see, there is a great deal of information contained on this sign that can go a long way in future renovations, as well as for ITM comparison requirements. Remember it was not required by NFPA 13 until 2007, many installing contractors and Authority Having Jurisdictions (AHJ) may not be aware of the requirement. Section 5.2 is the inspection section, simply do things look like they should? Do they appear to be in the proper operating state, not leaking, not damaged? That is the extent of inspections. Now for the fun stuff, Section 5.3 Testing. This is where the real work begins and where things can go wrong if not conducted in the proper manner. This section includes the testing of alarm devices, antifreeze systems and sprinkler testing. One thing you will no longer see in chapter 5 is the testing and calibration of gauges, this was moved to Chapter 13 in NFPA 25, 2017 edition.

The requirements for sprinkler testing are often misunderstood and implemented incorrectly. The typical question is, how many sprinklers are to be tested and from what areas do they need to be selected? The answer depends on how the building is designed. Different types of building environments and different manufacturers of sprinklers are all factors in the sampling process. Some research and conversations with the building owner should happen when sampling sprinklers for testing. The discussion should include sample area size. For example, a ten-story office building could be considered one sample area, but that could be broken down into several sample areas such as every two floors for five sample areas. The cost for testing would be more but if any sample fails, only the sprinklers from the sample area would need replaced not the entire building. Another discussion should be about different sprinkler types such as pendants and sidewalls. Samples from each type of sprinkler would need to be taken unless the sprinklers are from the same manufacturer, then they can be considered one sample. Chapter 5 also talks about protective coverings which are only allowed in spray areas and mixing rooms with specific material used for the covering.

Antifreeze testing is also covered in Chapter 5. There are many concerns with antifreeze such as all antifreeze shall be premixed solutions in compliance with the requirements of Section 5.3.4. This section requires glycerin to be no more than 38 percent and glycol must be no more than 30 percent by volume. As always there are additional rules and exceptions. There is also a sunset date of September 30, 2022 which requires all antifreeze solutions to be listed. This means that any existing antifreeze must be replaced with a listed solution or the antifreeze system must be replaced with another type of fire protection system.

Maintenance is one of the last sections in Chapter 5 and covers things such as the spare head box. Most of us think of this as an inspection item, but it falls under maintenance. It also tells us the sprinkler replacement requirements and that when a sprinkler is removed, it cannot be reused. This section also requires that a list of spare sprinklers be in the spare head box.

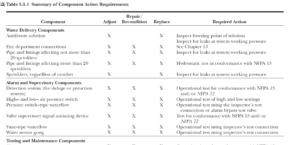

The remaining sections outline how to deal with dry systems that are waiting on replacement parts, marine systems, and component action tables. The component action table will be found in each chapter and provides guidelines on what shall take place when parts and pieces of the sprinkler system are repaired or replaced.

Chapters 5 and 13 will be the most utilized chapters in NFPA 25 and like all chapters within the standard; persons responsible for conducting any water-based ITM should be familiar with those requirements and where to find the specifics for the type of system or components they are working on, specifically when it comes to impairment procedures. Chapter 15 outlines how to handle preplanned and emergency impairment procedures but is one of the most unused chapters in the standard.